Improvement of Water-Repellent Swimsuits

On this page

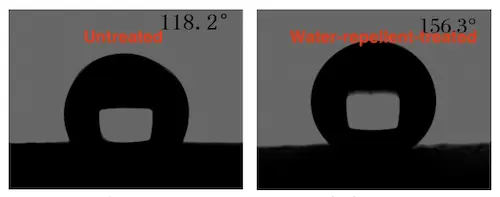

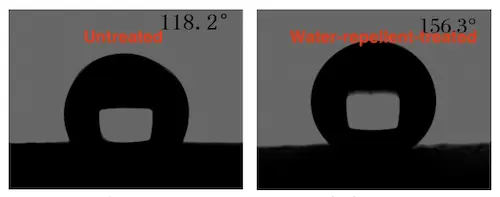

As shown in Figure 2, the water contact angle of untreated imported swimsuits is 118.2°, while the water contact angle of water-repellent-treated imported swimsuits is 156.3°, an increase of 38.1°, indicating an improvement in hydrophobic performance.

Figure 2 Water contact angle of imported swimsuits

Figure 2 Water contact angle of imported swimsuits

As shown in Table 1, the water-repellent treatment effectively improves the moisture resistance of swimsuits. The water repellency of the developed imported competition swimsuits reaches level 5, while that of untreated imported competition swimsuits is only level 3.

Table 1 Water repellency test results

Table 1 Water repellency test results

| Samples | Water repellency levels |

| Untreated imported swimsuits | 3 (small unconnected wet areas on the shower surface) |

| Water-repellent-treated imported swimsuits | 5 (no wetness on the shower surface, and no small water droplets on the surface) |

As shown in Table 2, after 30 repeated washings, the developed imported water-repellent competition swimsuit maintains a water repellency level of 5 and demonstrates excellent washability.

Table 2 Washability test results

Table 2 Washability test results

| Samples | Water repellency levels after 30 repeated washings |

| Untreated imported swimsuits | 3 (small unconnected wet areas on the shower surface) |

| Water-repellent-treated imported swimsuits | 5 (no wetness on the shower surface, and no small water droplets on the surface) |

The imported swimsuit used in this study already features shaping, wrinkle-free stitching, and a certain water-repellent coating. Therefore, based on the principle of hydrophobicity, a post-finishing method was adopted to combine constructing a rough surface and reducing the fabric’s surface energy to create a super water-repellent surface, enhancing the drag reduction effect. First, the water-repellent coating of the original swimsuit was removed; then fluorine-containing finishing agents and water-repellent enhancers were applied to the surface of the swimsuit to alter the fiber's surface structure and bond with it. Next, low surface energy materials such as silane and fluorosilane were used to reinforce the water-repellent finish, causing water to flow off the swimsuit’s surface, preventing it from becoming wet, and reducing friction resistance between the swimsuit and water.

Hydrophilicity and hydrophobicity refer to properties exhibited when water and solid surfaces come into contact. When a liquid comes into contact with a solid, it spreads along the solid surface. This is known as the wetting phenomenon between liquid and solid. The contact angle is typically used to reflect the degree of wetting. The contact angle refers to the angle between the tangent of the gas-liquid interface at the intersection of the gas, liquid, and solid phases and the solid-liquid boundary line. It measures the degree of wetting. For superhydrophobic surfaces, the water contact angle can be as high as 150° or more. In this study, the contact angle of the water-repellent-treated swimsuit reached 156.3°, which was 38.1° higher than that of the untreated swimsuit, achieving the goal of superhydrophobicity.

Table 3 Wrap floating test results

| Samples | Pieces | Movement time/s |

| Blank group | 30 | 11.386±0.058 |

| Coated untreated imported swimsuits | 30 | 11.433± 0.053** |

| Coated treated water-repellent imported swimsuits | 30 | 11.568 ± 0.052**## |

The results of the wrap floating test are presented in Table 3.

Note: ** indicates p < 0.01, compared with the blank group; # indicates p < 0.01, compared with the coated untreated imported swimsuit. As presented in Table 3, compared with the blank float, the movement time of the coated untreated imported swimsuit float increased by 0.411%, and the difference compared to the control group was significant (p < 0.01). The movement time of the coated water-repellent imported swimsuit float increased by 1.603%, and the difference compared to the control group was also significant (p < 0.01). Additionally, the movement time of the coated water-repellent imported swimsuit float was significantly higher than that of the untreated imported swimsuit, with a significant difference (p < 0.01).

As shown in Table 4, after wearing the imported swimsuit with water-repellent treatment, the 100m freestyle test time decreased by 1.25 seconds compared with the time achieved while wearing the untreated swimsuit, and the difference was significant (p < 0.05); however, compared to the swimmer's personal best 100m time, the 100m test time still increased by 0.47 seconds, and the difference was not significant (p > 0.05). Pressure difference resistance and shape resistance are primarily related to the swimmer's body shape and technical movements. Once the athlete's body develops to a certain extent and their technical movements become relatively stable, the most effective way to improve swimming speed is by reducing the frictional resistance between the skin surface and the water. Swimsuits can streamline the body, reduce friction between the skin surface and water, and minimize the wearer's energy loss. The key to swimsuit design is selecting appropriate materials to minimize resistance and reduce athletes' energy loss. The shark-skin swimsuit developed by Speedo has guided the direction of swimsuit design, and various companies continue to apply new materials and processes in swimsuit design. In this study, after applying nanomaterials for drag reduction treatment, the movement time of the floating objects coated with water-repellent-treated swimsuits was significantly higher than that of untreated swimsuits, with a significant difference (p < 0.01), indicating that water-repellent-treated swimsuits effectively improve drag reduction. After wearing the imported swimsuits with water-repellent treatment, the 100m freestyle test times were reduced by 1.25 seconds compared with the untreated swimsuits, and the difference was significant (p < 0.05).

Table 4 Swimming pool test results

Table 4 Swimming pool test results

| Scores | Pieces | Test time/s |

| Untreated swimsuits | 8 | 61.77±5.89 |

| The best | 8 | 60.05±6.77* |

| Water repellent treated swimsuits | 8 | 60.52±5.60* |

(1) After removing the general water-repellent coating from the imported finished swimsuits, the drag reduction effect can be significantly improved by reinforcing the water-repellent finish with fluorosilane-based low surface energy materials and then applying tetraethyl orthosilicate for nano-modification.

(2) Applying new materials for water-repellent finishing on the finished swimsuits can further enhance drag reduction performance while retaining the original bionic design structure, offering good potential for practical applications.

(2) Applying new materials for water-repellent finishing on the finished swimsuits can further enhance drag reduction performance while retaining the original bionic design structure, offering good potential for practical applications.