Preparation and Testing of Water-Resistant Swimsuits

On this page

More than 90% of the energy consumed by swimmers during swimming is used to overcome pressure resistance, shape resistance, and surface friction resistance in fluid mechanics. Swimsuits streamline the body and reduce resistance during swimming. As a result, with the continuous development of swimsuits, athletes' swimming performance has improved significantly. Studies have shown that freestyle performance, which is the least affected by technical factors, has greatly improved across short and long distances. The International Swimming Federation has stipulated that, as of 2010, swimsuits for men's events may only cover from the waist to the knees, and swimsuits for women's events may only cover from the shoulders to the knees. Additionally, the material of the swimsuits must be textiles, meaning the possibility of significantly increasing swimming speed through high-tech means is reduced. Therefore, this study uses nanotechnology to prepare water-repellent swimsuits that reduce friction resistance and explores their drag reduction performance.

Studies have shown that the combined effect of micro-nanostructure and hydrophobicity on the surface of an object is more likely to cause water flow slippage, with a slip length greater than that produced by a smooth hydrophobic surface. Therefore, the key to achieving drag reduction is to form a nanometer adsorption layer and ensure the surface has good hydrophobic properties. Nanomaterials that provide adsorption and strong hydrophobicity on pore walls may reduce drag, but different nanomaterials and treatment processes vary in their effectiveness. If only the surface of the material is hydrophobic without a supporting wall structure, no significant drag reduction can be achieved. The sol-gel method is a gentle technique requiring simple equipment and is highly operable. Peng and others used the sol-gel method to coat dodecyltrichlorosilane on the surface of polydimethylsiloxane, obtaining nano-scale SiO2 through acid catalysis. The surface of the super-hydrophobic coating had a contact angle of 160°. Junhong Zheng and others synthesized a fluorinated polymer through solution polymerization and applied super-hydrophobic finishing to cotton fabrics with a rough, porous structure at the micron level, achieving a contact angle of over 160°. With minimal impact on the fabric's application performance, excellent self-cleaning properties and water resistance were achieved. Xuanyu Zhang and others used the sol-gel method to cross-link the prepared SiO2/PDMS aerogel with cotton fabric, producing super-hydrophobic cotton fabric suitable for use in tents, advertising cloths, and kitchen cloths. In this study, the sol-gel method was employed for nano-modification. Tetraethyl orthosilicate (TEOS) and tridecafluorooctyl triethoxysilane (FAS) of different particle sizes were grafted onto the swimwear fabric surface and filled between the fiber gaps, forming an orderly micro-nano molecular concave-convex structure to achieve water repellency. After the nanomaterial was introduced, the nanoparticle adsorption layer changed the pore surface from hydrophilic to hydrophobic while simultaneously reducing pore size to achieve drag reduction.

Studies have shown that the combined effect of micro-nanostructure and hydrophobicity on the surface of an object is more likely to cause water flow slippage, with a slip length greater than that produced by a smooth hydrophobic surface. Therefore, the key to achieving drag reduction is to form a nanometer adsorption layer and ensure the surface has good hydrophobic properties. Nanomaterials that provide adsorption and strong hydrophobicity on pore walls may reduce drag, but different nanomaterials and treatment processes vary in their effectiveness. If only the surface of the material is hydrophobic without a supporting wall structure, no significant drag reduction can be achieved. The sol-gel method is a gentle technique requiring simple equipment and is highly operable. Peng and others used the sol-gel method to coat dodecyltrichlorosilane on the surface of polydimethylsiloxane, obtaining nano-scale SiO2 through acid catalysis. The surface of the super-hydrophobic coating had a contact angle of 160°. Junhong Zheng and others synthesized a fluorinated polymer through solution polymerization and applied super-hydrophobic finishing to cotton fabrics with a rough, porous structure at the micron level, achieving a contact angle of over 160°. With minimal impact on the fabric's application performance, excellent self-cleaning properties and water resistance were achieved. Xuanyu Zhang and others used the sol-gel method to cross-link the prepared SiO2/PDMS aerogel with cotton fabric, producing super-hydrophobic cotton fabric suitable for use in tents, advertising cloths, and kitchen cloths. In this study, the sol-gel method was employed for nano-modification. Tetraethyl orthosilicate (TEOS) and tridecafluorooctyl triethoxysilane (FAS) of different particle sizes were grafted onto the swimwear fabric surface and filled between the fiber gaps, forming an orderly micro-nano molecular concave-convex structure to achieve water repellency. After the nanomaterial was introduced, the nanoparticle adsorption layer changed the pore surface from hydrophilic to hydrophobic while simultaneously reducing pore size to achieve drag reduction.

Water-repellent finishing was performed on swimwear from the brand designated by FINA. The imported swimwear possess a certain degree of water repellency. First, the water-repellent coating was removed, and then a finishing agent with a special molecular structure was applied to the surface of the swimwear to alter the fiber's surface structure and improve bonding. Water flows down the surface of the swimsuit without wetting it, thereby reducing friction resistance between the swimsuit and the water.

The original water-repellent coating of the swimsuit should be removed by machine washing and alkaline treatment. After machine washing the swimsuit for 3 hours at a water temperature of 30°C, rinse, and dry. Then, soak the swimsuit in a 2 g/L acetic acid solution for 15 minutes and wash it in cold water (below 20°C) until neutral. Stir the machine-washed swimsuit in an 8% sodium hydroxide solution for 15 minutes at a water temperature of 90°C, wash with hot water (above 80°C) until neutral, and then soak in a 2 g/L acetic acid solution for 15 minutes before washing again in cold water (below 20°C) until neutral.

Nano-amphiphobic and amphiphilic binary structures, such as fluorine-containing finishing agents and water-repellent enhancers, are used to finish swimsuits with water-repellent properties. Slowly add 80 g/L of finishing agent FP-01 and water to the container. Adjust the pH to 5.0-6.0 with 1 g/L of acetic acid, then add 5 g/L of enhancer FP-11 and 4 g/L of MgCl as a penetrant. Stir at low speed for 5 to 10 minutes until the water-repellent finishing agent is evenly mixed. Before the water-repellent finishing, the swimsuit is soaked in an acetic acid solution (pH 5-6) for 1 hour. After drying, it is immersed in the water-repellent finishing agent for 1 hour, placed in a 120°C oven to dry, and then baked at 170°C for 2 minutes. The water-repellent treatment is repeated three times.

Reinforce the water-repellent finishing using fluorosilane-based low surface energy materials. Soak the swimsuit, treated with the water-repellent finishing agent, in a 0.5% FAS/ethanol solution. Ultrasonicate it for 30 minutes; dry it at room temperature, and then bake it at 120°C for 1 hour.

Add 5 mL of TEOS and 1.056 g of FAS to 25 mL of ethanol and mix evenly. Then, add an ammonia/ethanol solution (5 mL of ammonia and 75 mL of ethanol) dropwise to the flask, stirring for 15 minutes to ensure even mixing, and continue stirring at room temperature for 12 hours. Soak the swimsuit sample in the prepared sol-gel solution for 30 minutes, dry it at room temperature, and bake it at 120°C for 1 hour.

The water contact angle is measured using a video contact angle tester. The sample is fixed on a slide with double-sided tape to ensure it is flat and uniform in thickness. Then, place the sample on the storage table, drop 3 µL of water onto the sample, use the video contact angle tester to capture an image of the droplet on the sample, and measure the water contact angle using the experimental instrument.

The moisture resistance of the fabrics is tested according to GB/T 4745-1997. Test conditions include a water temperature of (27 ± 2) °C, with 3 specimens from each sample tested in parallel. The water repellency level is evaluated by comparing the experimental fabric with a standard reference image.

Water resistance is tested according to GB 12799-1991. The detergent concentration is 2g, the bath ratio (fabric: washing liquid) is 1:30, and the washing temperature is (30.0 ± 3.0) °C. After 30 repeated wash cycles, the water repellency is reassessed.

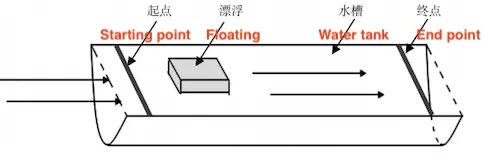

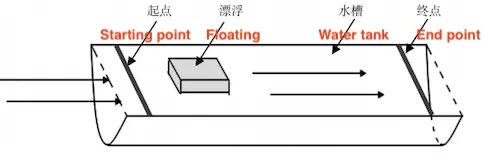

Test device: The swimming tank is a horizontally placed semicircular tank with a diameter of 0.2 m and a length of 15 m, with a constant flow of water introduced into the tank. Floating objects are those with a specific volume and density that allow them to completely float on the surface of the water flow. A schematic diagram of the test device is shown in Figure 1.

Test method: Under the same conditions and at the same flow rate, the movement times of blank floats, floats wrapped with untreated swimsuits, and floats wrapped with water-repellent-treated swimsuits were tested, respectively. A total of 120 groups of experiments were conducted for each type of float, and 30 groups of experimental data with an error margin within 5% were selected.

Figure 1 The test device

Test method: Under the same conditions and at the same flow rate, the movement times of blank floats, floats wrapped with untreated swimsuits, and floats wrapped with water-repellent-treated swimsuits were tested, respectively. A total of 120 groups of experiments were conducted for each type of float, and 30 groups of experimental data with an error margin within 5% were selected.

Figure 1 The test device

Testers: Eight professional freestyle swimmers, all at the national level 2 or above, who had undergone at least two years of professional team training and agreed to participate in this test. The athletes were (15.9 ± 1.5) years old, (176.8 ± 7.38) cm tall, and (64.06 ± 8.60) kg in weight.

Test method: The freestyle swimming style, which is least affected by technique, was used as the test swimming style. The athletes wore one-piece, knee-length swimming trunks and performed a 100 m full-strength swimming test. A double-blind control experiment was conducted, with the team members wearing swimsuits randomly, but each was only worn once. The test lasted 1.5 days. The athletes took a test in the morning of the first day, the afternoon of the first day, and the afternoon of the second day. They completed a 2000 m warm-up before each test. The test conditions were: ambient temperature of 30°C, relative humidity of 60%, and water temperature of 28°C.

Test method: The freestyle swimming style, which is least affected by technique, was used as the test swimming style. The athletes wore one-piece, knee-length swimming trunks and performed a 100 m full-strength swimming test. A double-blind control experiment was conducted, with the team members wearing swimsuits randomly, but each was only worn once. The test lasted 1.5 days. The athletes took a test in the morning of the first day, the afternoon of the first day, and the afternoon of the second day. They completed a 2000 m warm-up before each test. The test conditions were: ambient temperature of 30°C, relative humidity of 60%, and water temperature of 28°C.

SPSS 15.0 statistical software was used for the statistical analysis. One-way ANOVA and paired-samples t-test were used for inter-group difference analysis. The data were expressed as mean ± standard deviation. A p-value of less than 0.05 was considered significant.